3D Laser & Fabrication is a beacon of precision and excellence in metal fabrication, in Brampton, Toronto. With a commitment to quality, innovation, and customer satisfaction, we’re a trusted partner for businesses seeking top-notch metal fabrication services in Brampton.

In this blog, we delve into the fascinating world of metal fabrication. Let’s explore the processes, technologies, and the unique approach that sets us apart in the industry.

Understanding Metal Fabrication

Metal fabrication is a multifaceted process that involves the transformation of raw metal materials into finished products or components. This process is crucial across various industries, from construction and automotive to aerospace and beyond. Metal fabrication encompasses a range of techniques. This includes cutting, bending, welding, and assembling, all aimed at creating products with precise dimensions and high structural integrity.

At 3D Laser & Fabrication, our team of skilled professionals leverages advanced technologies and years of expertise to deliver tailored metal fabrication solutions that meet the diverse needs of their clients. From prototyping to production runs, the company is equipped to handle projects of varying scales and complexities.

Cutting-Edge Technology: The Heart of 3D Laser & Fabrication

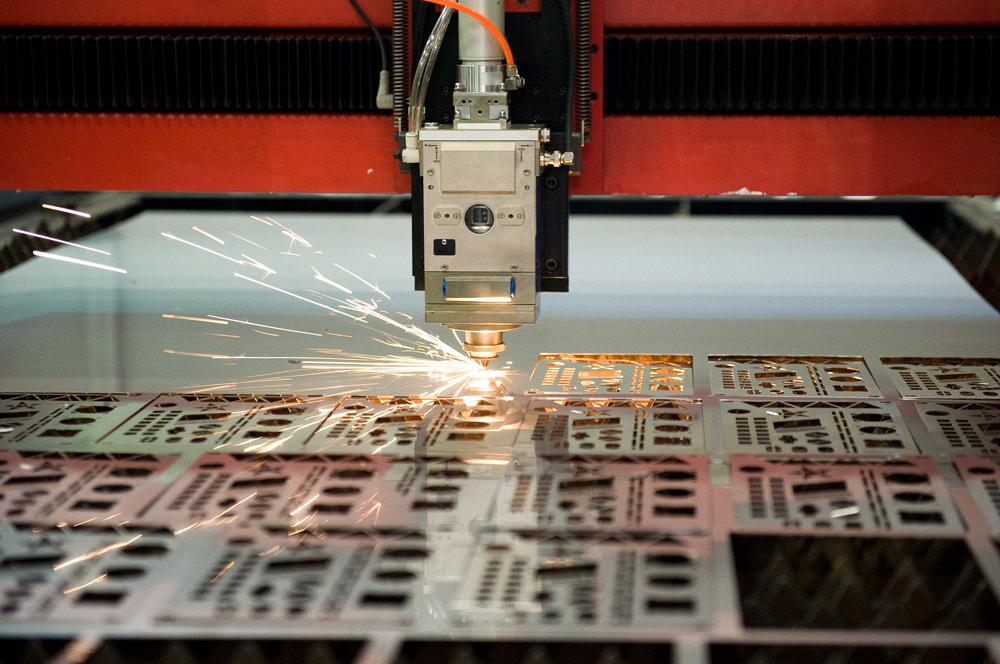

Central to 3D Laser & Fabrication’s success is our integration of cutting-edge technology into every facet of the metal fabrication process. We use of state-of-the-art laser cutting technology is a prime example of their commitment to precision and efficiency.

Laser cutting has revolutionized metal fabrication in Brampton by offering unparalleled accuracy and speed. The process involves the use of a high-powered laser to cut through metal sheets with remarkable precision. This technology allows for intricate designs and complex shapes to be cut with ease, ensuring that the final products meet the most stringent specifications.

Furthermore, the laser cutting machines at 3D Laser & Fabrication are equipped with 3D capabilities, enabling the fabrication of three-dimensional components with incredible accuracy. This capability is particularly beneficial in industries where intricate, geometrically complex parts are required.

Welding Excellence

Welding is a fundamental aspect of metal fabrication, and at 3D Laser & Fabrication, it is treated as both an art and a science. The company employs skilled welders who bring a wealth of experience to the table. Their expertise ensures that welded joints are not only structurally sound but also aesthetically pleasing.

Different metals require different welding techniques. At 3D Laser & Fabrication we’re well-versed in working with a variety of materials, including stainless steel, aluminum, and carbon steel. Whether it’s MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, or other specialized techniques, the team has the know-how to deliver flawless welds that stand the test of time.

Customization and Prototyping

One of our standout strength’s is our dedication to customization and prototyping. We understand that each client has unique requirements, hence we collaborate closely with clients from conceptualization stage to final product. This iterative process ensures that the end result aligns perfectly with the client’s vision and specifications.

Prototyping is a crucial step in the metal fabrication process, allowing clients to assess and refine their designs before full-scale production begins. Our prototyping services provide clients with tangible models that not only showcase the aesthetics of the final product but also allow for functional testing. This proactive approach significantly reduces the risk of errors and ensures that the final product meets or exceeds expectations.

GET YOUR CUSTOM QUOTE TODAY!

Quality Assurance and Compliance

3D Laser & Fabrication places a paramount emphasis on quality assurance. Our company adheres to stringent quality control measures at every stage of the metal fabrication process. From material inspection to final assembly, each step is meticulously monitored to ensure that the end product meets the highest industry standards.

In addition to quality, compliance with industry regulations and standards is a top priority for 3D Laser & Fabrication. We stays abreast of evolving industry norms and regulations to ensure that its products not only meet but exceed the required benchmarks for safety, durability, and performance.

Local Impact and Community Engagement

Beyond its technical prowess, our company is deeply committed to making a positive impact on the local community. We actively engage in community outreach programs and support local initiatives. We’re actively contributing to the social and economic development of Brampton and the greater Toronto area.

Moreover, we recognizes the importance of sustainability in today’s business landscape. The company embraces environmentally friendly practices, such as recycling scrap metal and optimizing production processes to minimize waste. By adopting sustainable practices, we not only reduces its environmental footprint but also sets an example for responsible business practices.

Looking for the best Metal Fabrication in the Toronto area?

Look no further. Our experts are here to help you. Whatever your requirements, we can deliver the best. Contact us now.

Conclusion

In the realm of metal fabrication, 3D Laser & Fabrication stands as a beacon of excellence, combining cutting-edge technology, skilled craftsmanship, and a commitment to client satisfaction. From metal laser cutting Toronto to precision welding and beyond, our company’s comprehensive approach to metal fabrication sets us apart in the competitive landscape of Brampton, Toronto, and beyond.

As industries continue to evolve and demand increasingly complex and precise metal components, we’re ready to meet all challenges. With a dedication to innovation, quality, and community engagement, the company is not just a metal fabrication service provider in Brampton; it’s a trusted partner for businesses seeking top-tier solutions in the ever-expanding world of metal fabrication.